The Problem

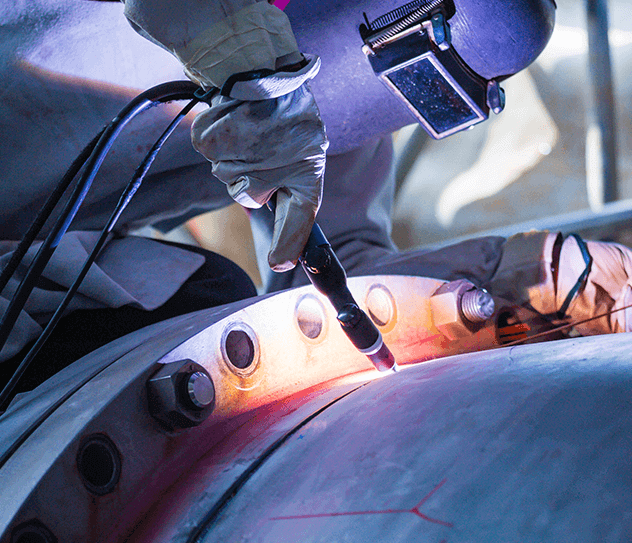

Breakages on cast iron parts of engines like liners, cylinders, diesel heads, bedplates, bearings and every stressed part of an engine is a serious problem for the engineer that deals with its repair.

It is known that by using welding processes (arc welding, oxy-fuel welding) in aforementioned parts is impossible that undesirable effects that are caused by high temperatures in the repaired parts cannot be avoided.

The change in the original structure of the metals, distortions and tensions, are the most serious drawbacks of the thermal repairs, and result in less resistance in compression, expansion and stresses of the section that was repaired and thus its breakage once again.

The Solution

By using cold stitching Metalock, all aforementioned drawbacks are avoided. Repair takes place in ambient temperature, without the use of flame, stitching fractures utilizing stiching locks (Locks) made of high strength special alloys of different technical and geometrical characteristics, which are inserted transverse to the fracture with the help of high pressure pneumatic tools.

The fracture is then filled between the locks with special studs providing stability and water-pressure tighting. In case special reinforcement is needed in stressed parts, high strength alloy inserts (Masterlocks) are inlaid by cold working.

Non Destructive Testing (NDT) in the repaired parts takes place after the end of the Metalock process with the use of special testing tools like spray (dye check), magnetic particles and Ultrasonic.

The Advantages

Repair with Metalock stitching restores the original stability and water-tighting of the repaired part without altering the structure of the metal. It dampens and absorbs compression stresses.

Maintains relieved conditions of internal stresses where the rapture occurred. Distributes load away from fatigue points.

The vast majority of Metalock repairs can be done in situ with no need of any dismantling or spadework. No turning and planing is needed after the stitching process is done.

The metalock procedure

step-by-step description

- Step 1

-

Step 2

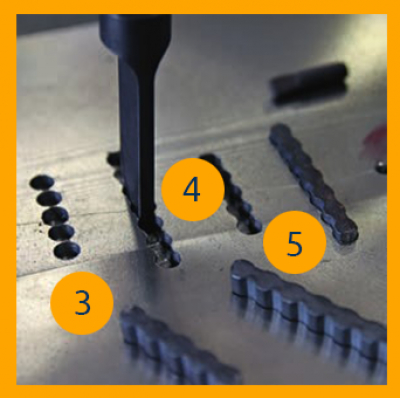

(3) The Metalock key is a special molded part made of a special alloy, whose size and length are fitted to the corres- ponding crack.

(4) The holes are linked using a pneumatic chipping hammer and fitted to the shape of the Metalock key.

(5) Individual layers of keys are inserted into the openings and caulked into an interlocking form, which is practically integ- rated into the base metal. - Step 3

- Step 4

- Step 5

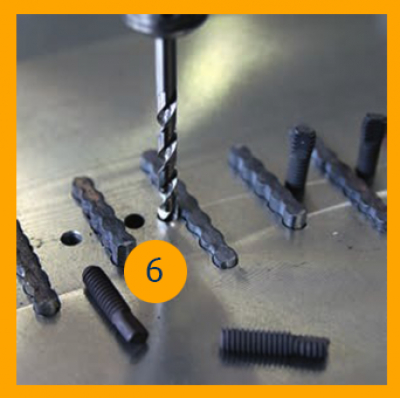

- Step 6